How to Measure Products for Custom paper boxes

Introduction

Creating custom paper boxes requires precise measurements to ensure your product fits perfectly while providing adequate protection during shipping and handling. Whether you're packaging delicate items, retail products, or promotional materials, accurate measurements form the foundation of effective packaging design. This comprehensive guide will walk you through the entire process of measuring products for custom paper boxes, covering essential tools, measurement techniques, and professional tips to achieve optimal results.

Understanding Packaging Dimensions

Before measuring your product, it's crucial to understand the three fundamental dimensions of any box:

1. Length (L): The longest side of the box when looking at the opening

2. Width (W): The shorter side of the box when looking at the opening

3. Height (H): The side perpendicular to the length and width (depth of the box)

These dimensions are always listed in the order of Length × Width × Height (L × W × H). This standardization helps manufacturers and designers communicate clearly about box specifications.

Essential Tools for Accurate Measurements

Gather these tools before starting your measurement process:

1. Digital Calipers: For precise measurements of small items (accurate to 0.01 mm)

2. Measuring Tape: Flexible tape for measuring curved or irregular surfaces

3. Ruler or Straight Edge: For measuring flat surfaces

4. Angle Finder: For measuring angles on non-rectangular items

5. Notepad and Pen: To record all measurements

6. Camera: To document the product from multiple angles

7. Scale: To measure product weight (important for determining box strength)

Step-by-Step Measurement Process

1. Prepare Your Product

Clean the product surface and remove any accessories or detachable parts that won't be packaged together. If the product has movable components, decide whether to measure them in their extended or collapsed position based on how they'll be packaged.

2. Measure Basic Dimensions

Using your calipers or ruler, measure each dimension at the product's widest points:

- Length: Measure from left to right at the longest point

- Width: Measure from front to back at the widest point

- Height: Measure from top to bottom at the tallest point

For irregular shapes, measure the extreme points in each dimension. Record measurements in both metric (millimeters) and imperial (inches) units to accommodate different manufacturing standards.

3. Account for Protective Packaging

Add extra space for protective materials:

- Bubble Wrap: Add 3-5mm per side

- Foam Inserts: Add 5-10mm per side

- Tissue Paper: Add 1-2mm per side

- Corrugated Padding: Add 2-3mm per side

The total additional space needed depends on the fragility of your product. For extremely delicate items, you might need to add up to 25mm of padding on each side.

4. Consider Product Orientation

Determine how the product will be positioned in the box:

- Upright Position: Common for bottles, vases, and vertical items

- Laying Flat: Better for books, frames, and flat items

- Custom Angle: Required for some specialty products

The orientation affects which dimension becomes the "height" of your packaging.

5. Measure Irregularly Shaped Products

For non-rectangular items, follow these techniques:

- Spherical Items: Measure diameter and add padding all around

- Cylindrical Items: Measure diameter and height separately

- Triangular Items: Measure all three sides and the height

- Complex Shapes: Create a rectangular "bounding box" that would contain the entire item

For very irregular shapes, consider creating a template or 3D scan of the product to ensure accurate measurements.

6. Account for Product Movement

Add 1-3mm of "wiggle room" to prevent the product from being too tight in the box, which could cause damage during temperature changes or minor impacts during shipping.

7. Measure Weight

Weigh your product accurately, including all internal packaging materials. This measurement helps determine:

- Required box material thickness

- Necessary structural reinforcements

- Appropriate closure methods

8. Consider Special Requirements

Document any special packaging needs:

- Hanging Hooks: Measure their position and required clearance

- Display Windows: Measure the exact area to be exposed

- Handles or Cutouts: Note their dimensions and placement

- Moisture Sensitivity: Determine if additional space is needed for desiccants

Calculating Final Box Dimensions

After gathering all measurements, use this formula to calculate your ideal box dimensions:

Box Length = Product Length + (Padding × 2) + Wiggle Room

Box Width = Product Width + (Padding × 2) + Wiggle Room

Box Height = Product Height + (Padding × 2) + Wiggle Room

Always round up to the nearest millimeter or 1/8 inch to ensure adequate space.

Common Measurement Mistakes to Avoid

1. Measuring Without Prototype: Always create a physical mockup before finalizing dimensions

2. Ignoring Temperature Effects: Materials expand/contract with temperature changes

3. Forgetting About Assembly: Some products require space for on-site assembly

4. Overlooking Internal Structures: Dividers, inserts, and partitions take up space

5. Neglecting to Measure Multiple Samples: Products can vary slightly in size

6. Disregarding Shipping Constraints: Check carrier size limitations before finalizing

Advanced Measurement Techniques

1. 3D Scanning

For complex products, 3D scanning creates a digital model that can be used to design perfect-fitting packaging. This method is particularly useful for:

- Organic shapes

- Sculptural items

- Products with intricate surface details

2. Volume Displacement

For items that can't be easily measured with straight edges:

1. Submerge the product in water

2. Measure the displaced water volume

3. Calculate equivalent rectangular dimensions that would contain that volume

3. Parametric Modeling

Use CAD software to create adjustable 3D models that automatically calculate required packaging dimensions based on product parameters.

Material Considerations Affecting Dimensions

Different packaging materials behave differently and may require adjustments:

1. Corrugated Board: Adds 2-5mm to internal dimensions due to thickness

2. Rigid boxes: Walls are thicker, requiring more internal space adjustment

3. Folding Cartons: Thin material but may need scoring allowances

4. Foam Inserts: Compress under pressure, requiring precise calculations

Testing Your Measurements

Before mass production, always test your measurements with:

1. Physical Mockups: Create sample boxes from inexpensive materials

2. Drop Tests: Ensure the product is properly protected

3. Shipping Tests: Send sample packages through actual shipping channels

4. Climate Tests: Expose to different temperatures and humidity levels

Documentation Standards

Maintain consistent documentation for all packaging measurements:

1. Measurement Sheets: Standardized forms with all dimensions

2. 3D Drawings: Isometric views with annotated dimensions

3. Tolerance Specifications: Acceptable variation ranges

4. Revision History: Track all changes to measurements

Working with Packaging Manufacturers

When communicating with packaging suppliers:

1. Provide clear dimensional drawings with all critical measurements

2. Specify which dimensions are fixed and which can be adjusted

3. Clarify whether dimensions are internal or external

4. Indicate measurement tolerances (±1mm, ±0.5mm, etc.)

5. Share physical samples whenever possible

Digital Tools for Packaging Measurement

Several software solutions can assist with packaging measurements:

1. Packaging Design Software: Specialized tools for creating dielines

2. CAD Programs: For precise technical drawings

3. 3D Modeling Software: To visualize packaging in virtual space

4. Augmented Reality Apps: To preview packaging on actual products

Sustainability Considerations in Packaging Measurement

Proper measurement contributes to sustainable packaging by:

1. Minimizing material waste through precise sizing

2. Reducing shipping volume and weight

3. Optimizing pallet configuration for transportation

4. Eliminating need for excessive protective materials

Industry-Specific Measurement Guidelines

Different products require specialized measurement approaches:

1. Food Products

- Account for possible expansion (freezing, fermentation)

- Include space for oxygen absorbers or moisture control

- Consider stacking requirements

2. Electronics

- Measure including all cables and accessories

- Account for anti-static materials

- Include space for documentation and warranty cards

3. Cosmetics

- Consider bottle orientation to prevent leakage

- Measure including outer wrapping or decorative elements

- Account for tester samples if included

4. Pharmaceutical

- Strict requirements for protective materials

- Space for informational inserts and leaflets

- Tamper-evident features may affect dimensions

Future Trends in Packaging Measurement

Emerging technologies are changing how we measure for packaging:

1. AI-Assisted Measurement: Machine learning algorithms that suggest optimal packaging dimensions

2. Smart Packaging: Integrated sensors that monitor space utilization

3. On-Demand Packaging: Systems that create custom-sized boxes in real-time

4. Blockchain Tracking: Immutable records of packaging specifications

Conclusion

Accurate product measurement forms the foundation of successful custom Paper box packaging. By following these detailed measurement techniques, avoiding common pitfalls, and leveraging modern tools, you can create packaging solutions that perfectly fit your products while providing optimal protection. Remember that packaging is both an art and a science—while precise measurements are crucial, always leave room for practical testing and adjustments. With careful measurement and attention to detail, your custom paper boxes will enhance your product's presentation, protection, and overall customer experience.

English

English

Español

Español

Portugues

Portugues

Pусский

Pусский

Français

Français

Deutsch

Deutsch

日本語

日本語

한국어

한국어

العربية

العربية

Italiano

Italiano

Nederlands

Nederlands

Ελληνικά

Ελληνικά

Svenska

Svenska

Polski

Polski

ไทย

ไทย

Türk dili

Türk dili

हिन्दी

हिन्दी

Indonesia

Indonesia

Melayu

Melayu

Tiếng Việt

Tiếng Việt

Magyar

Magyar

қазақ

қазақ

বাংলা

বাংলা

עִברִית

עִברִית

čeština

čeština

Soomaali

Soomaali

မြန်မာ

မြန်မာ

فارسی

فارسی

українська

українська

norsk

norsk

Gaeilge

Gaeilge

беларускі

беларускі

Română

Română

ພາສາລາວ

ພາສາລາວ

Filipino

Filipino

lietuvių

lietuvių

Suomalainen

Suomalainen

slovenský

slovenský

اردو

اردو

հայերեն

հայերեն

Igbo

Igbo

български

български

سنڌي

سنڌي

Hrvatski

Hrvatski

galego

galego

català

català

basa jawa

basa jawa

Кыргызча

Кыргызча

тоҷикӣ

тоҷикӣ

Србија

Србија

Hawaii

Hawaii

latvija

latvija

slovenija

slovenija

ਪੰਜਾਬ

ਪੰਜਾਬ

hua moni

hua moni

bosna

bosna

Монгол

Монгол

Azərbaycan

Azərbaycan

Malta

Malta

ខ្មែរ

ខ្មែរ

中文(繁体)

中文(繁体)

Afrikaans

Afrikaans

Sango

Sango

मैथिली

मैथिली

Татар

Татар

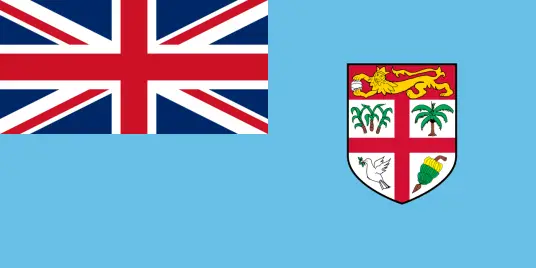

Fiji

Fiji

Telepun

Telepun

wël

(0)